VISION

Virtual Sensors from chemistry-based models for Intelligent Online Virtual Calibration (VISION)

The VISION project partners develop an innovative system software to calibrate and optimise the control system as used in HiL-platforms. The platform contains a real ECU hardware in a virtualised Real Driving Emissions (RDE) environment. The aim is to accurately predict fuel consumption for powertrain performance and estimate the emissions to be considered in the upcoming emissions legislation.

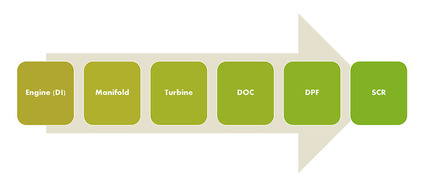

The sub-project at LOGE focuses on the development of a real-time capable model for the exhaust manifold and the efficient integration of catalytic converter models for exhaust gas aftertreatment in virtual HiL-platforms.

The aim is to accurately predict fuel consumption for powertrain performance and to estimate the increased number of emission types to be taken into accountin the upcoming emissions legislation.

The development planned in this project is divided into three main tasks:

- Development of software for detailed chemistry-based modelling of the chemical processes in the engine exhaust manifold using CPV (Combustion Progress Variable) based technology.

- Programming an FMI interface to allow the exhaust manifold model to be connected to a variety of HiL-platforms.

- The detailed chemistry-based simulation of different exhaust aftertreatment systems to validate different EATS configurations for HiLsimulations and coupling of the non-real-time capable catalyst LOGEcat with HIL systems.