Imogen

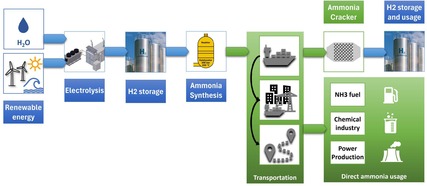

Hydrogen production, storage, and transport remain the greatest challenges for the realization of a sustainable hydrogen economy and a key to the success of the energy transition. In order toutilize hydrogen as an energy carrier, it is necessary to provide hydrogen at a satisfactorily high density while ensuring the highest safety standards in line with demand. The storage of hydrogen in non-cryogenic hydrogen-rich liquids -so-called hydrogen vectors -has recently become the focus of increasing interest. This approach involves the demand-orientated production of hydrogen through thermal cracking or chemical decomposition of hydrogen vectors.

Ammonia does not contain any carbon atoms, which create environmentally harmful carbon oxides between the decomposition products and does not require any additional water to keep the decomposition reaction going. Furthermore, ammonia can be almost completely decomposed at relatively low temperatures, either with the help of a suitable catalyst or a membrane reactor that shifts the NH3 decomposition reaction to the end products.

A promising hydrogen scenario based on ammonia is that H2 is produced overseas and transported to Europe. The conversion of ammonia to hydrogen can take place directly in harboursor where additional energy is required.

The primary aim of this project is to design and control an ammonia cracker in such a way that hydrogen production as part of the overall hydrogen-ammonia-hydrogen system is accurately predicted and energetically optimiseddepending on further use. This requires ensuring a high quality of the simulations from the ammonia tank to the hydrogen pipeline as well as precise knowledge of the dependencies of the control variables. At the same time, the energy input, particularly in the form of thermal energy, should be minimised. Furthermore, the system must also be designed for the high pressures at which ammonia is usually supplied.

Within the Imogen project we propose the development of a software product that is intended to resolve the physical and chemical processes involved in catalytic ammonia cracking. For the first time at LOGE, a virtual heat exchanger is to be developed that makes it possible to map the special features of heat management due to the endothermic nature of the catalytic splitting of ammonia. In addition to this, our project partner RWTH is pursuing the goal of deriving an innovative process for the development of predictive controls for complex, transient systems based on the overall controlled system that has been developed. This is to be carried out using the example of the ammonia cracker system in conjunction with a possible high-temperature fuel cell (SOFC) as a hydrogen consumer.