LOGEcat ES

Catalyst Modeling. Reimagined.

Design any reactor. Simulate any mechanism. Achieve breakthrough insights – fast.

LOGEcat ES is a sound and powerful simulation tool for exhaust after treatment systems. From AOC to TWC, it enables engineers and scientists to model, test, and optimize catalysts with accuracy and flexibility.

Design and optimize your catalytic converters for real-world conditions with built-in kinetic mechanisms and flow solvers.

Revolutionize Your Catalyst Modeling – Faster Insights. Smarter Decisions.

Any Reactor. Any Mechanism. No Limits.

Don’t let software constrain your innovation. Design and simulate any reactor setup with full control over reaction mechanisms – all in one powerful platform.

High-Precision Catalyst Modeling, Made Simple

Go beyond the basics. Run detailed 1D and quasi-3D simulations to uncover performance drivers, optimize efficiency, and predict real-world behavior with confidence.

Master Both Steady-State and Transient Scenarios

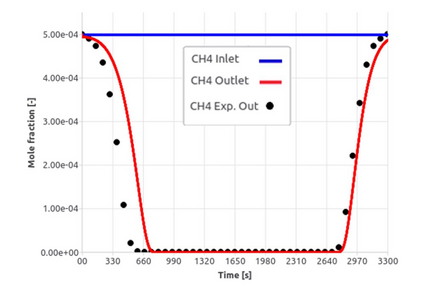

Whether you're optimizing continuous processes or analyzing dynamic events, we deliver accuracy where it matters most.

Intuitive UI. Professional Power.

Say goodbye to clunky interfaces. Our clean, flexible GUI helps you focus on results, not on learning the software.

Next-Generation Chemistry Solver

Built from the ground up for catalytic processes, our solver combines speed, accuracy, and robustness – so you can trust every result.

Instant Access to Reaction Mechanisms – Fully Customizable

Get started fast with a curated library of detailed reaction mechanisms, then fine-tune them to your exact needs.

Typical Applications

- Three Way Catalyst (TWC)

- Diesel Oxidation Catalyst (DOC)

- Methane Oxidation Catalyst (MOC)

- Lean NOx Trap (LNT)

- Selective Catalytic Reduction (SCR)

- Ammonia Oxidation Catalyst (AOC/AMOX)

- Ammonia Slip Catalyst (ASC)

Meaningful visualization of the results

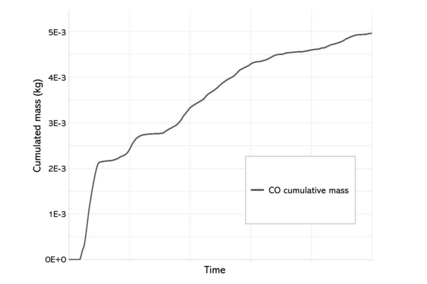

- Online visualization of the simulation’s progress,

- Easily compare your simulation results with experimental data,

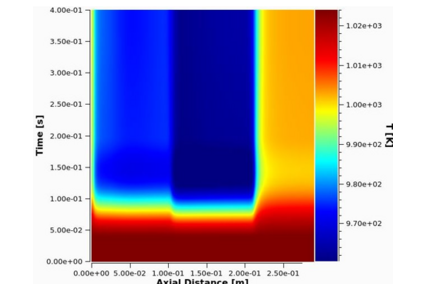

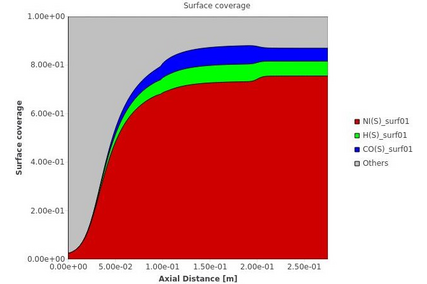

- 2D-visualization of dynamic surface coverage on the catalyst surface,

- 3D-visualization of temperature change,

- Static figures or animated sequences,

- Vizualisation of reaction paths.